Preciseness and a smooth process of packaging for FMCG products are guaranteed.

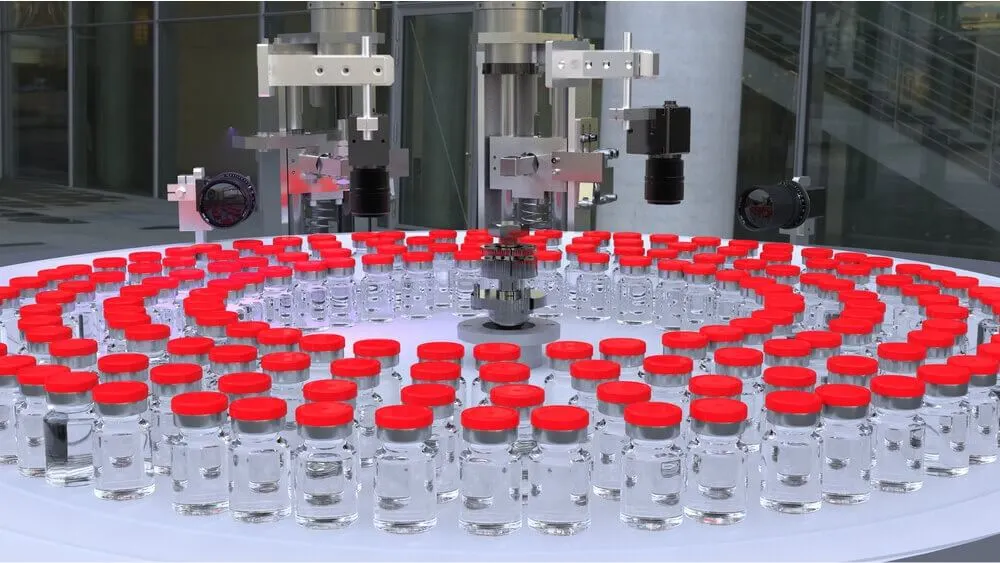

A packaging inspection solution is a detailed system designed to ensure the quality, accuracy, and compliance of packaging processes in various industries. It involves the use of advanced technologies, including cameras, sensors, and software algorithms, to inspect and verify packaging elements such as labels, barcodes, seals, and overall product presentation.

Excellent quality and accuracy are directly associated with product safety, consistency, and traceability. Specifically, issues with packaging during production can not only impact the prestige of the product and brand but also create a serious public health issue.

The automated packaging inspection solution by OptoPixel is now capable of solving even the most rigid concerns in the production line. These solutions are now an integral part of the quality control procedure, reducing the chances of human error, and enabling quick and accurate detection and reduction of defective products.

Excellent quality and accuracy are directly associated with product safety, consistency, and traceability. Specifically, issues with packaging during production can not only impact the prestige of the product and brand but also create a serious public health issue.

The automated packaging inspection solution by OptoPixel is now capable of solving even the most rigid concerns in the production line. These solutions are now an integral part of the quality control procedure, reducing the chances of human error, and enabling quick and accurate detection and reduction of defective products.

FMCG Industry

Food safety and quality are critical in the food and beverage industry. Packaging inspection solutions help ensure that products are packaged correctly, labeled accurately, and free from contaminants.

Pharmaceutical Industry

In the pharmaceutical industry, packaging inspection solutions are used to verify the accuracy of packaging, labeling, and serialization of pharmaceutical products.

Automotive Industry

Automotive parts and components often require precise packaging to prevent damage during transportation. Packaging inspection helps maintain the quality of automotive products.

Error: Contact form not found.

Error: Contact form not found.